Our solutions

With our unique portfolio of carton, bag-in-box, and spouted pouch, we work in partnership with our customers to bring food and beverage products to consumers around the world in a safe, sustainable, and affordable way.

Invented for better

2025 marks a milestone in packaging history as we honor 70 years since the invention of the original bag-in-box package.

Explore the history of inventionWe’re on a journey to create packaging for better

Packaging that gives more to people and the planet than it takes out.

Innovations

SIG DomeMini

Our on-the-go carton bottle offers a new drinking experience and helps reducing plastic.

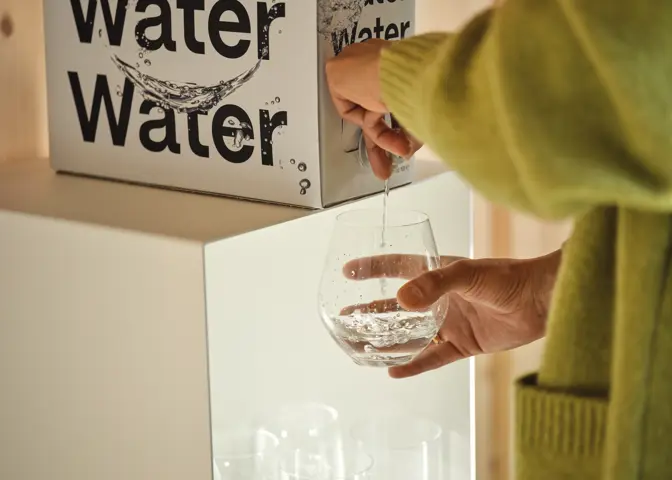

SIG SureFill 44

Fill bag-in-box packaging quickly and accurately with our automated, dual-lane filling solution.

SIG AeroCap Pouch

Maintain flavors, textures, and nutrition with the first pre-made, aseptic spouted pouch.

Connect with us

Have a question or want to connect?

We’d love to hear from you. Simply fill out our contact form and we’ll get back to you shortly!

Stay connected. Stay ahead.

Follow us on LinkedIn to get the latest insights, news, and stories that shape our industry. Be part of the conversation.

Get latest insights right into your inbox

Sign up for our monthly newsletter. Join us on our journey of packaging for better.

Latest blog posts

June 24, 2025

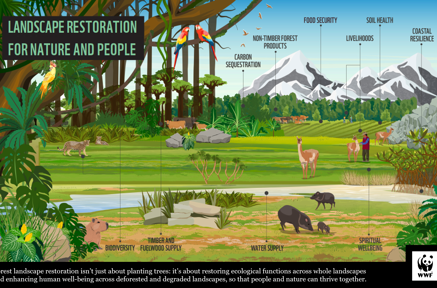

How WWF and SIG, together with 25 other leading companies, are working to help forests thrive

Together, these companies are helping conserve over 1.3 million hectares of forests and improving management across an additional 2.7 million hectares.

April 23, 2025

Beyond tree planting

Why companies should invest in landscape programmes for impact

April 10, 2025

Expert take: what makes baby food unique

The business of feeding little consumers is complex and requires going the extra mile.

Let us hear from the SIG expert about the building blocks for success in this category.

Make your work matter for better

Find your career path at SIG

At SIG, we believe in driving change for better. We strive to create a positive impact for the society, guided by our sustainability goals.

CareersLatest press releases

June 23, 2025

Germany: Hochwald pioneers shift to alu-layer-free aseptic cartons in Europe with SIG Terra packaging material

As SIG experiences a shift and demand towards aseptic cartons without aluminum layer, Hochwald, one of the leading dairies in Europe, is at the forefront of this move as it launches UHT milk in SIG cartons without aluminum layer. Using the packaging material SIG Terra Alu-free further reduces the already low carbon footprint of SIG standard packaging material by up to 34%*.

May 27, 2025

SIG Drinksplus enables TH true MILK’s launch of UHT chocomalt snack drinks with oats or nata de coco in aseptic cartons

TH true MILK, a major player and innovator in Vietnam’s dairy and beverage sector, continues to expand its product offering with the launch of two new snack drinks for children: Chocomalt with hearty oats or chewy nata de coco – both offering a fun and nutritious snacking experience in a convenient aseptic carton. This marks TH true MILK’s expansion of its dairy portfolio, made possible with the SIG Drinksplus technology.

May 27, 2025

SIG Foundation expands “Cartons for Good” initiative to Thailand

Following the success of its pilot project in Bangladesh, the SIG Foundation is proud to announce the expansion of its flagship “Cartons for Good” initiative to Thailand. In collaboration with Ampol Food, a leading food and beverage innovator in Thailand, the project is using SIG’s filling technology to transform surplus mangoes and longkong into nutritious pudding for elderly people in need.

Explore more

SIG Foundation

Strengthening civil society and creating positive impacts for the environment.