ALCA Corp

is a leading supplier of tropical fruit ingredients, exporting to over 70 countries and supplying bulk packaging for major baby food, beverage, and healthy snack brands. With three factories and more than 60 years of combined expertise, ALCA is renowned for its high-quality aseptic juices and purees.

Their challenge

ALCA sought to expand its portfolio and market reach by:

- Launching innovative, convenient fruit ingredient formats

- Reducing operational complexity and costs for aseptic pouch filling

- Offering additional co-packing services to enable new collaborations

- Ensuring food safety, quality, and sustainability for global customers

- Traditional spouted pouch filling required third-party pre-sterilization, adding time and cost. ALCA needed a solution that combined speed, flexibility, and uncompromising safety

Solution

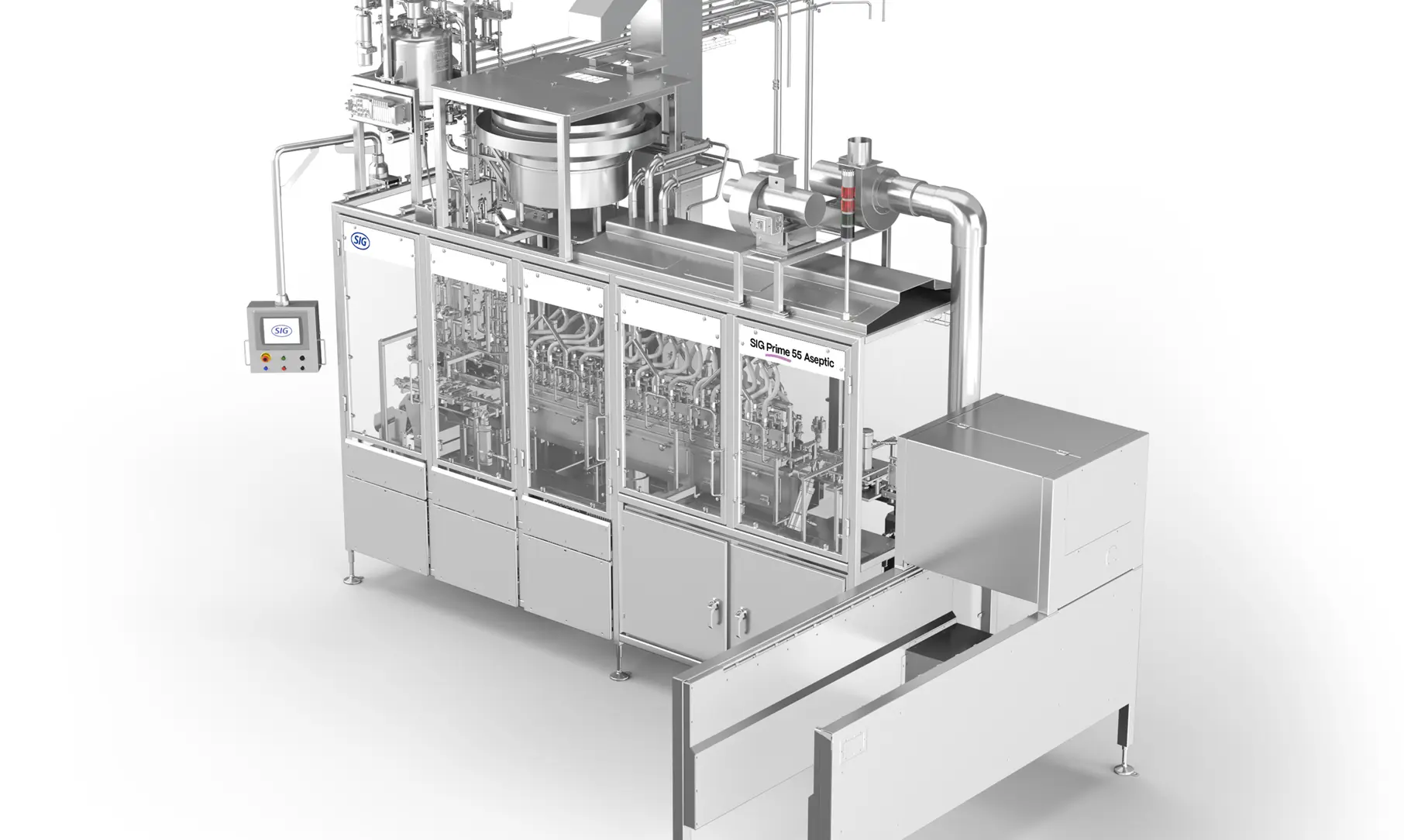

SIG Prime 55 In-line Aseptic

Next-generation spouted pouch filling system with in-line sterilization – eliminates third-party pre-sterilization of spouted pouches. SIG has thereby combined its longstanding experience in the field of aseptic pouch filling with decades of expertise in aseptic carton filling technology with in-line sterilization.

High output

Up to 55 pouches per minute, with flexible filling volumes (30ml–500ml).

SIG CloverCap closure

Easy-open, tamper-evident, and consumer-friendly.

Farm to pouch pilot brand

First aseptic banana purée pouch launched as proof of concept, gathering market feedback and showcasing new technology.

Clean Commit

ALCA also leverages the Clean Commit logo – a movement, logo and online resource for educating families about the benefits of aseptic packaging.

Impact and benefits

Innovation

ALCA is the first worldwide to launch products using SIG’s new in-line sterilization technology for spouted pouches, setting a benchmark for aseptic spouted pouch filling.

Operational efficiency

In-line sterilization reduces operating costs and simplifies the production process, enabling rapid time-to-market for new products.

Portfolio expansion

ALCA’s new aseptic pouch offering allows for additional co-packing services and opens doors for brand collaborations, starting with banana and MD2 pineapple purees.

Consumer education & trust

The Clean Commit initiative helps consumers understand the value of aseptic packaging – keeping food safe, fresh, and nutritious for up to 12 months, reducing waste and energy use.

Positive market response

ALCA’s new product offering enabled immediate new customer wins, including a co-packing agreement with a leading US brand for organic products, signed during Anuga 2025 trade show, Cologne, Germany.

Why it matters

ALCA’s partnership with SIG delivers:

- Modern, convenient packaging solution aligned with consumer trends

- Enhanced brand differentiation and shelf appeal

- A platform for further product innovation and market expansion

- A showcase of SIG’s technology as a catalyst for sustainable growth in the fruit ingredient sector

At-a-glance

Filling system

SIG Prime 55 In-line Aseptic

SKUs

Banana purée, MD2 pineapple

Pouch closure

SIG CloverCap

Filling volumes

30ml–500ml

Launch location

Anuga 2025, Cologne, Germany