2025 marks a milestone in packaging history as we honor 70 years since the invention of the original bag-in-box package. From revolutionizing liquid protection and transportation in 1955 to today's state-of-the-art, circularly recyclable solutions, our commitment to innovation remains unwavering.

A history of invention

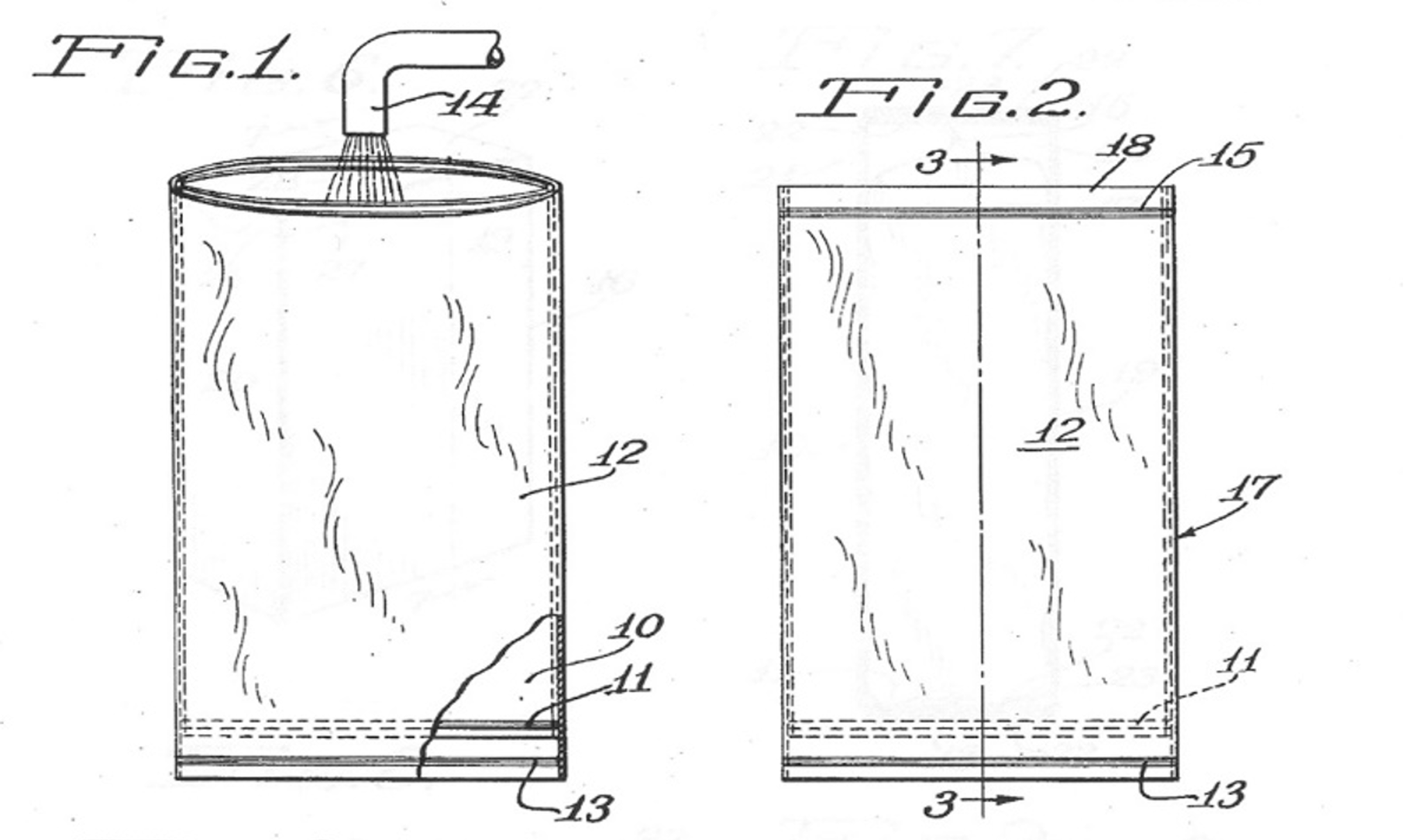

1955: William R. Scholle invents bag-in-box

William R. Scholle invents the first bag-in-box package, revolutionizing distribution and storage of liquids.

Originally designed for industrial chemicals, Scholle Packaging (now SIG) recognizes the packaging’s value in food and beverage.

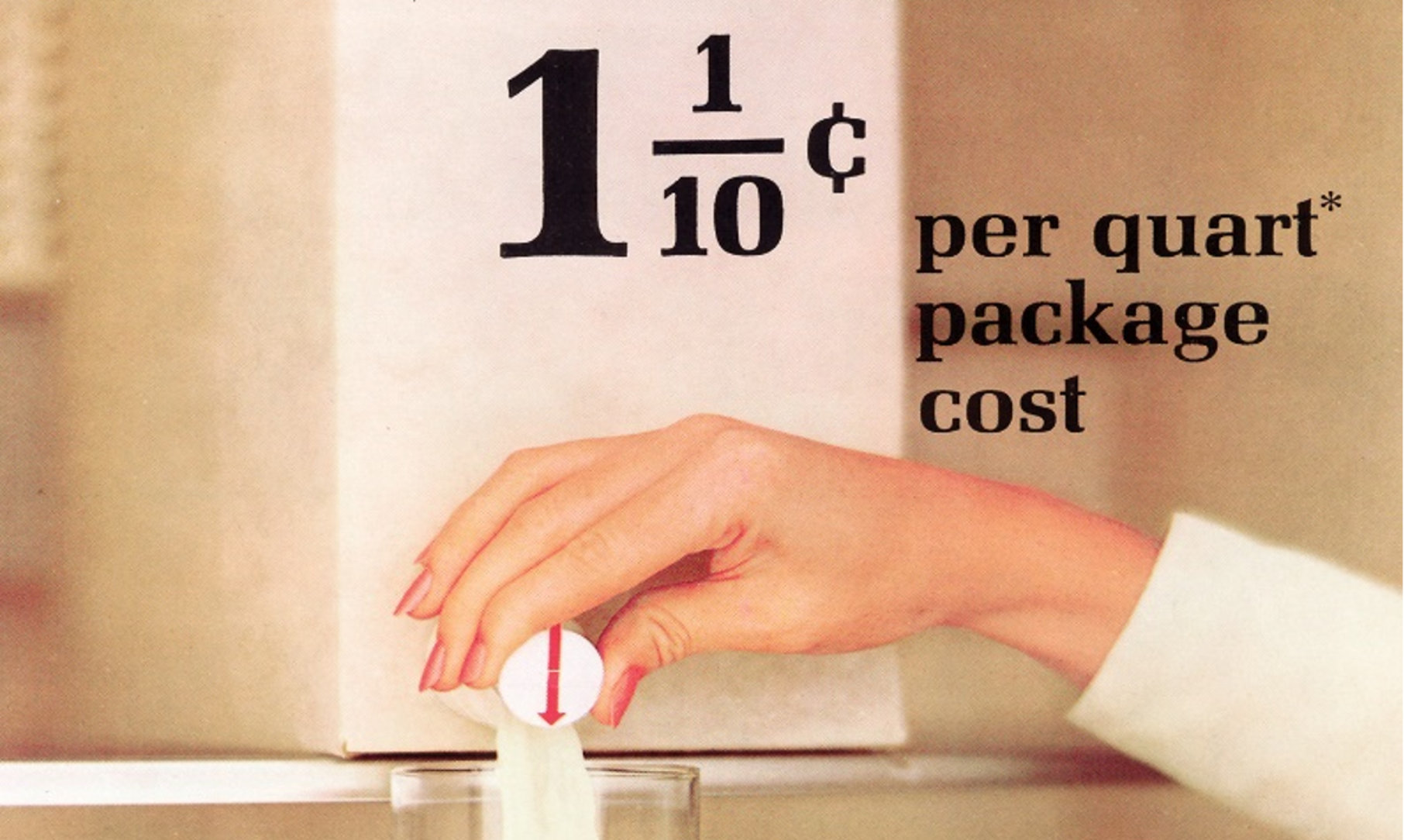

1950s: The original bag-in-box

Bag-in-box packaging categories are expanded into dairy, which is delivered directly into American homes.

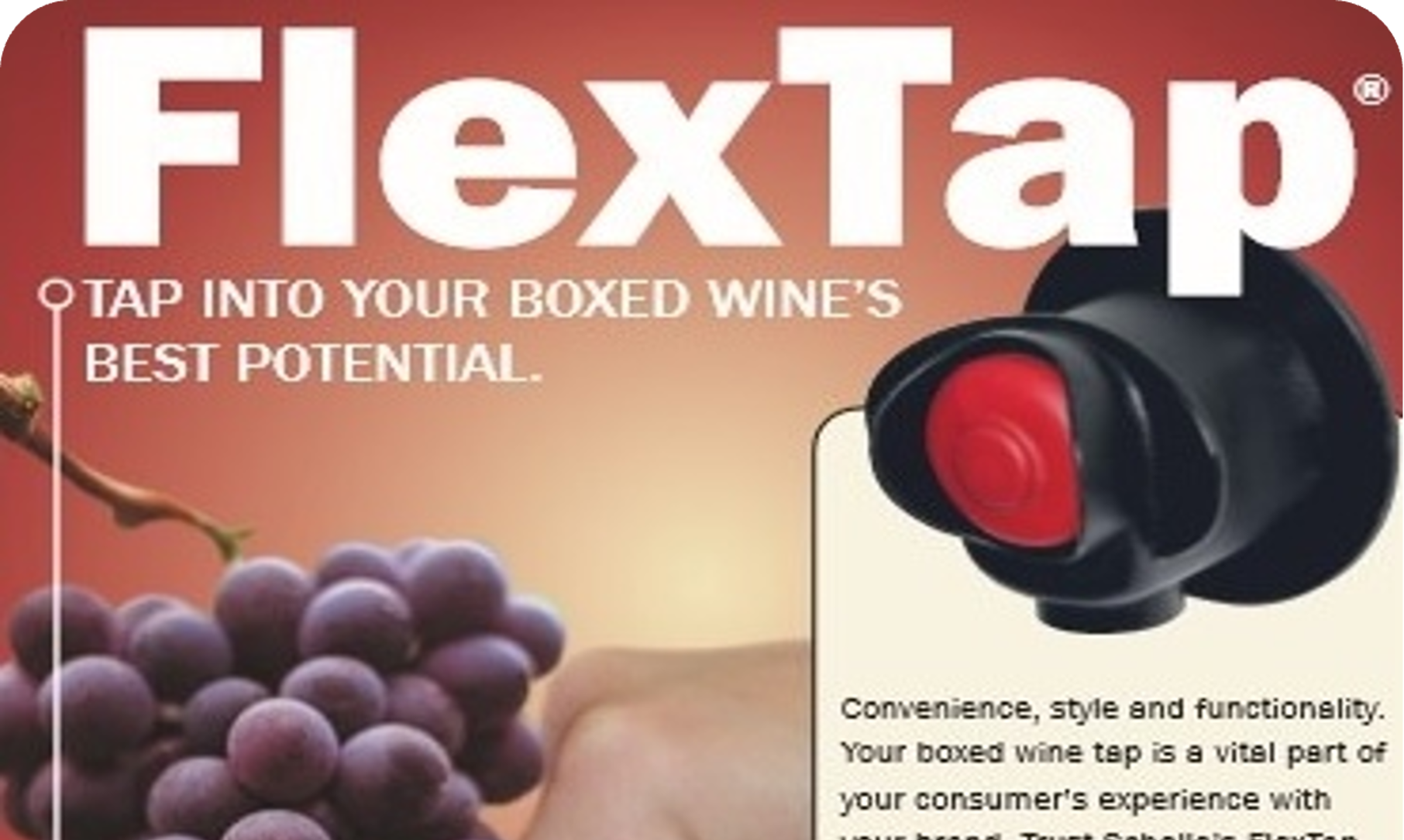

New, consumer-friendly taps are created for people of all ages, beginning our long history of innovating unique ways to fill and evacuate liquids from bag-in-box.

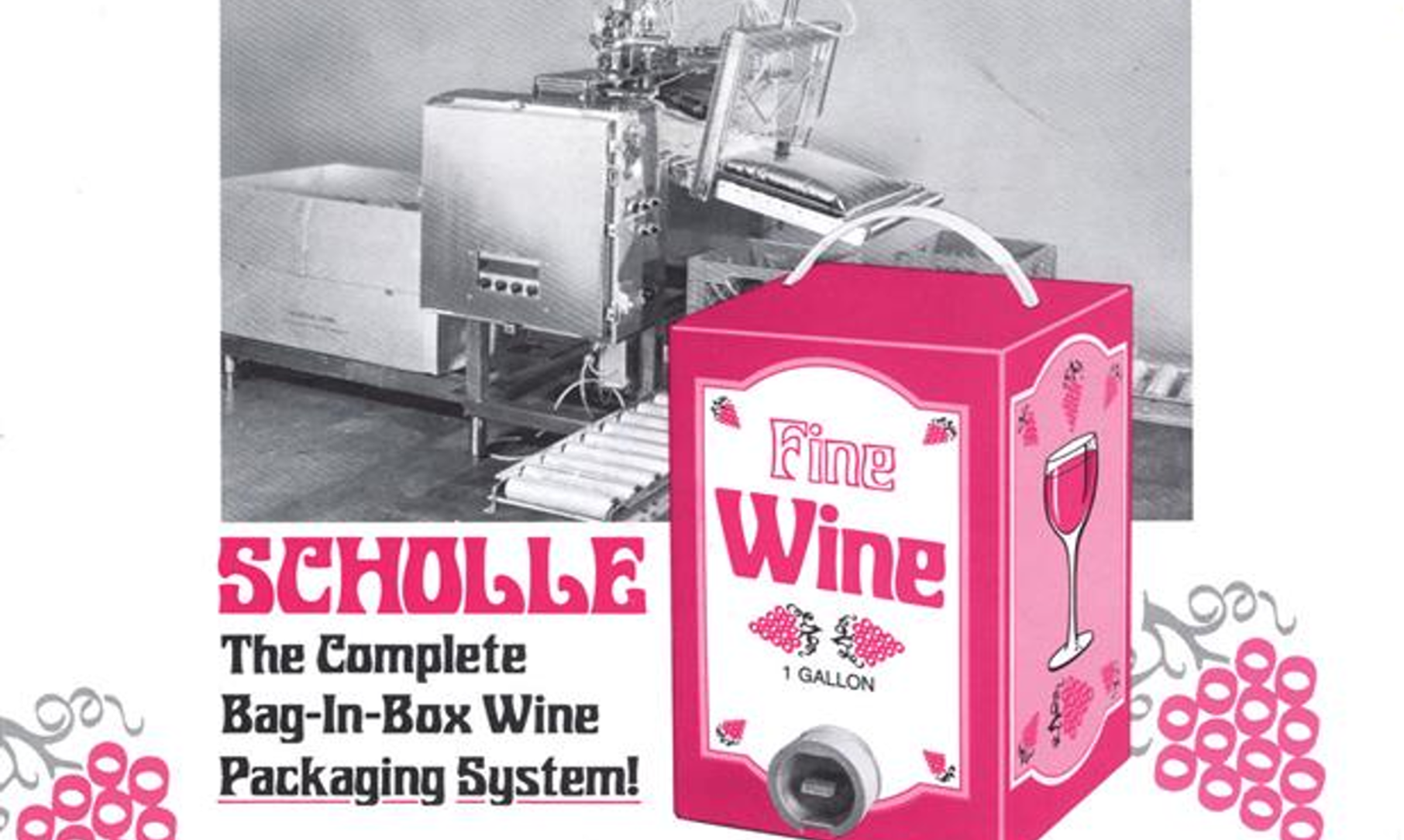

1960s: A decade of firsts

We introduce the world’s first automatic bag-in-box filling equipment.

We launch the first commercially viable bag-in-box packaging system for wine, in Australia. This innovation sets the stage for the BIB wine category to grow for decades to come.

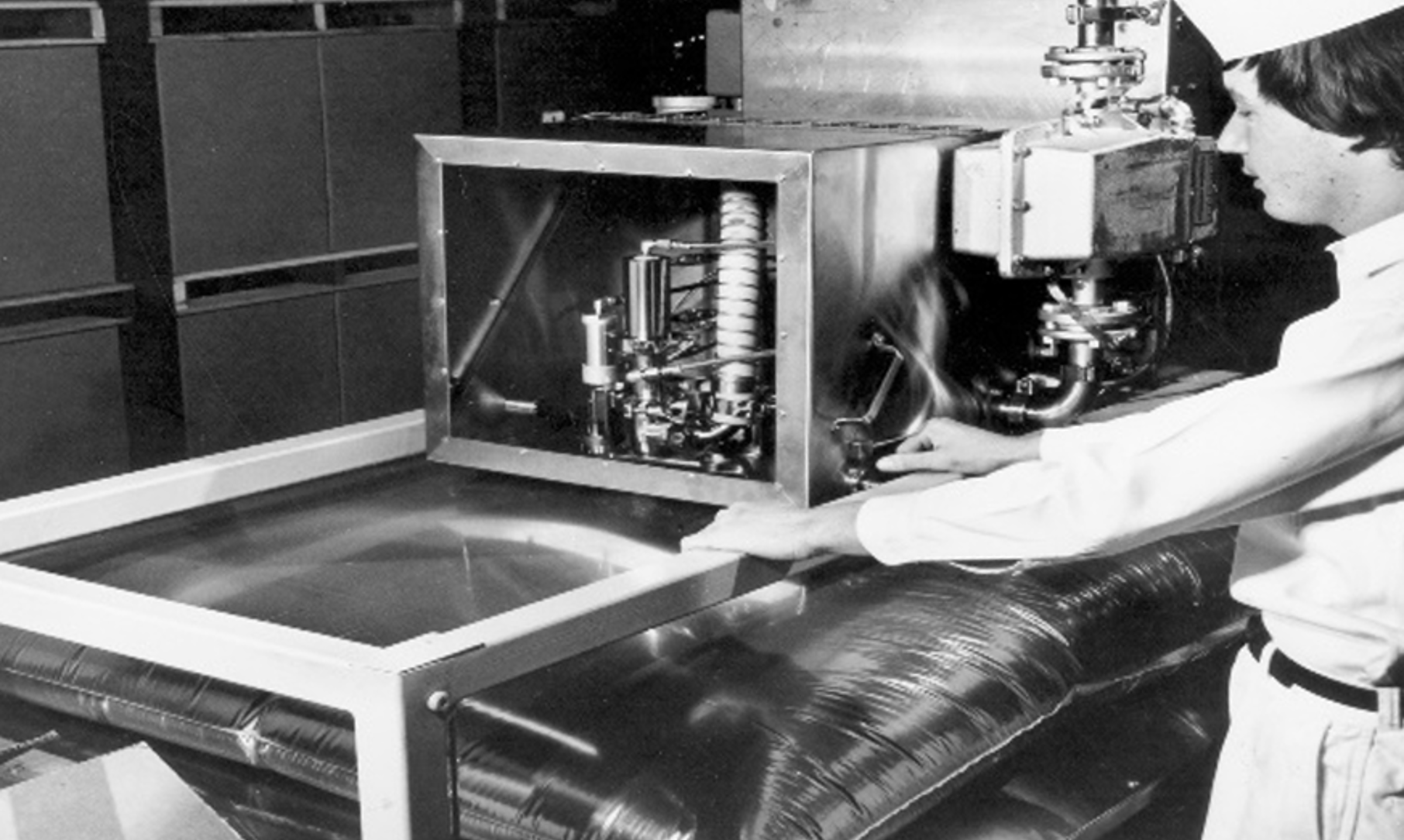

1970s: Go big. Go bulk!

Together with scientists at Purdue University, the company develops bulk-size bag-in-box packaging and filling systems that can fill and store high-acid products.

Developed to safely and economically ship juice products from Brazil, bulk BIB goes on to become a standard in industrial fruit and vegetable categories like tomato.

1970s: Farms and foodservice

Since the late 1970s, we provided bulk bag-in-box packaging to Morningstar, the world’s largest tomato grower.

The company pioneers the first BIB system for post-mix syrups, enabling carbonated soft drink companies to replace steel kegs with a more efficient solution for foodservice. This innovation now serves millions of sparkling beverages worldwide daily.

1980s: Dairy, meet aseptic

We develop the first low-acid aseptic bag-in-box system, opening new possibilities for dairy categories.

This innovation enables the conversion of milk, ice cream mix, and coffee creamers to BIB, enabling improvements in food waste, economics, and sustainability for dairies and foodservice outlets worldwide.

1990s: Better films, less waste

Our continuous innovation drives barrier film technology to a point where metallized film is no longer required for most products’ shelf-life requirements, even up to one year.

Removing aluminum from films while maintaining product quality is great for consumers and the environment.

2000s: Speed. Safety. Taste.

We advance bag-in-box filling with Vapor Sterilization Technology (VST), switching from steam to vapor peroxide for faster, safer, and more efficient sterilization.

We enable the premiumization of boxed wine with improved barrier films, smarter filling, and ergonomic taps. Allowing our customers to offer quality products at affordable prices has left a lasting impression on the wine market.

2010s: Press. Blend. Pour.

We enhance foodservice with the Connect fitment family, enabling QSRs to produce blended beverages like smoothies and frappes at the touch of a button.

Paired with aseptic filling, BIB packs with Connect fitments safely and efficiently deliver beverage concentrates to consumers worldwide.

2020s: Invented to recycle.

We advance design-for-recycling with our bag-in-box packaging, introducing the world’s first circularly-recyclable package, as recognized by the Association for Plastic Recyclers.

This breakthrough drives new opportunities across multiple categories, bringing circular-recycling closer to reality.

Beyond

Designed for recycling

‘for better’ is behind everything we do, and that means we will continue develop and make packaging that is better for consumers and our planet.

Smart dispensing

We’ve always been at the forefront of smart dispenser technology and will elevate the segment further, making life easier for operations in restaurants around the word.

Global growth

We will continue our quest to bring bag-in-box solutions to a global customer base with industry-leading production capabilities and capacity.

Breakthroughs in Bag-in-Box: faster, better, greener solutions