Connected filling lines with more than 800,000 data points, combined with the expertise of our SIG System Experts, deliver measurable value every day. Our global Reliability & Performance Centers transform raw machine data into actionable insights that drive performance, efficiency, and long-term value for our customers.

Directly measurable benefits

Transforming data into insights for our customers

Optimizing Overall Equipment Effectiveness (OEE)

Increasing filling machine performance

Achieving a proven higher first-time-fix rate

Ensuring smart operations for our customers

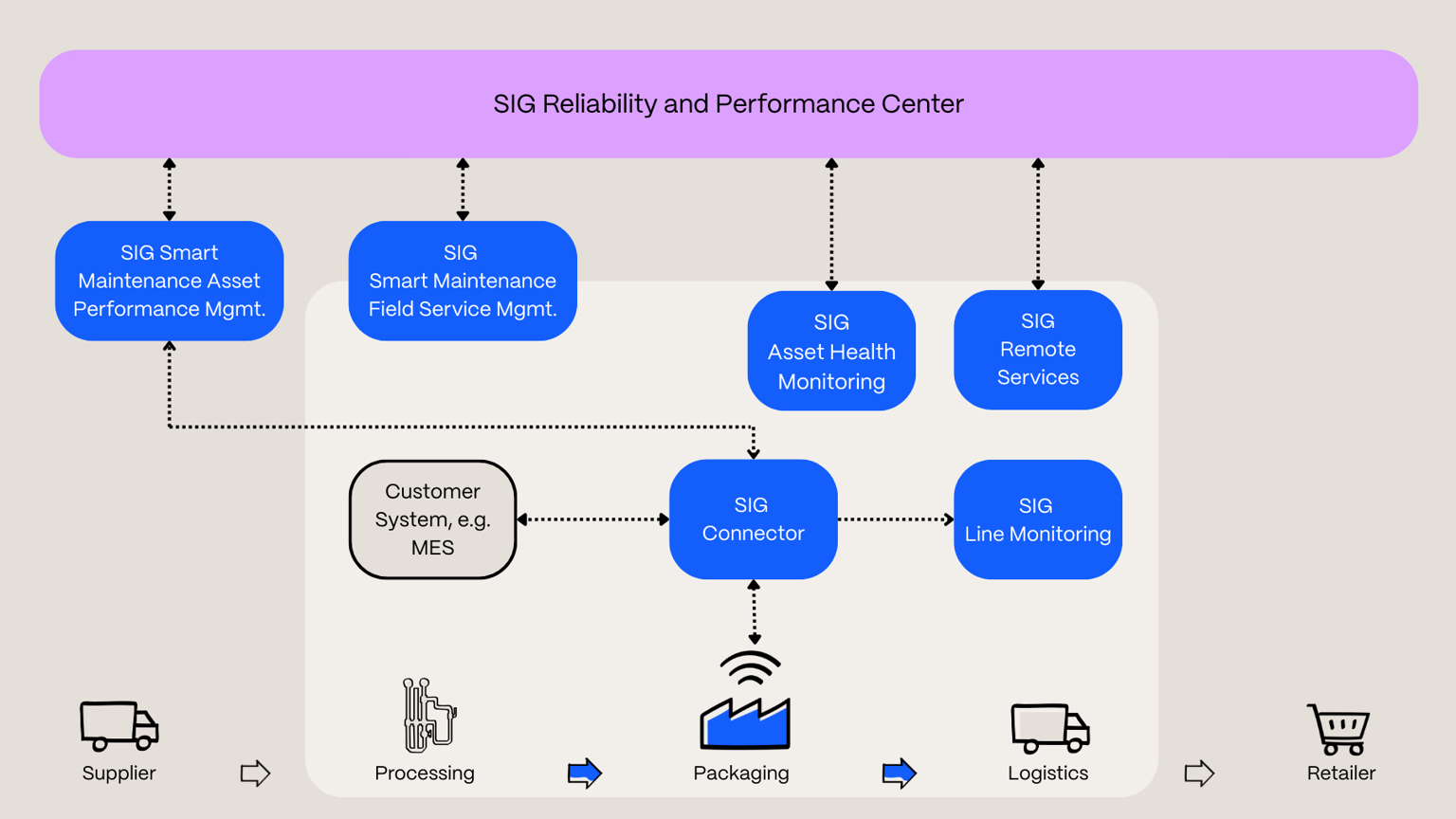

We design smart production systems that blend digital intelligence with best‑in‑class service capabilities. Our approach ensures intelligent asset performance built on a strong Total Cost of Ownership (TCO) mindset.

To secure the reliability and performance of our installed base, SIG applies a structured, ISO‑aligned asset‑management approach. By continuously monitoring connected machine data and integrating deep engineering expertise, we can:

- Detect issues early

- Predict failures

- Optimize service actions

This requires:

- Maintaining a clear and consistent asset registry

- Standardizing filling machine data collection

- Applying methodologies such as Reliability Centered Maintenance (RCM)

- Creating a continuous feedback loop between field performance and product design

The result

higher uptime

reduced lifecycle costs

greater customer value across the entire installed base

SIG Digital & Remote Solutions

Success cases

As part of SIG’s global commitment to maximizing filling line performance and enabling data‑driven operational excellence, our customers benefit from close collaboration with SIG’s regional Reliability and Performance Centers and technical experts. Through this partnership, producers gain actionable insights, targeted guidance, and measurable improvements across their filling operations.

Nadec

relies on SIG to minimize unplanned downtimes and boost the availability of its production lines. Supported by the SIG Reliability Center team in Dubai, Nadec has leveraged in‑depth equipment data analysis to drive measurable performance improvements within just one year. This collaborative, data‑driven approach has led to an

- avoided loss of approximately 1.2 million packs and

- achieved a 20% reduction in unplanned downtime,

demonstrating the strong impact of proactive reliability management.

FrieslandCampina Thailand

partners with SIG to transform operational data into actionable insights that elevate asset productivity. Guided by SIG Reliability Experts from the Asia Pacific South Technical Center, the team implemented a data‑driven improvement approach that delivered significant performance gains within just one year. This collaboration led to a

- 5% increase in Total Efficiency of the filling line and a

- 5% improvement in Technical Efficiency,

demonstrating the strong value of proactive reliability management and expert consultation.

Britvic Brasil

relies on SIG’s remote system experts to significantly enhance the availability of its production lines. Through continuous remote support delivered by specialists at the SIG Reliability and Performance Center in Curitiba, ebba has achieved strong, measurable improvements within just one year. This collaboration resulted in an

- avoided loss of approximately 1.1 million packs,

- a remarkable ~90% remote troubleshooting success rate, and

- 145 hours of reduced waiting time

thanks to minimized travel requirements – clearly demonstrating the impact and efficiency of expert remote support.

Our locations

Our Reliability & Performance Centers – located across Europe, Asia Pacific, the Americas, and IMEA – play a vital role in strengthening our value proposition and enabling high-performance operations around the globe.