Monitor the health of your assets

Staying on top of how your assets are performing is vital to long-term success. 90% of our customers report that preventing downtimes is a critical issue- and with SIG Asset Health Monitoring, one plant experienced a 20% reduction in unplanned downtimes across ten SIG fillers.

SIG Asset Health Monitoring is a solution for condition-based maintenance, designed to measure the wear and tear of parts and equipment and provide online monitoring to anticipate issues, recommend preventative measures, and offer solutions to optimize availability and reduce unplanned downtime.

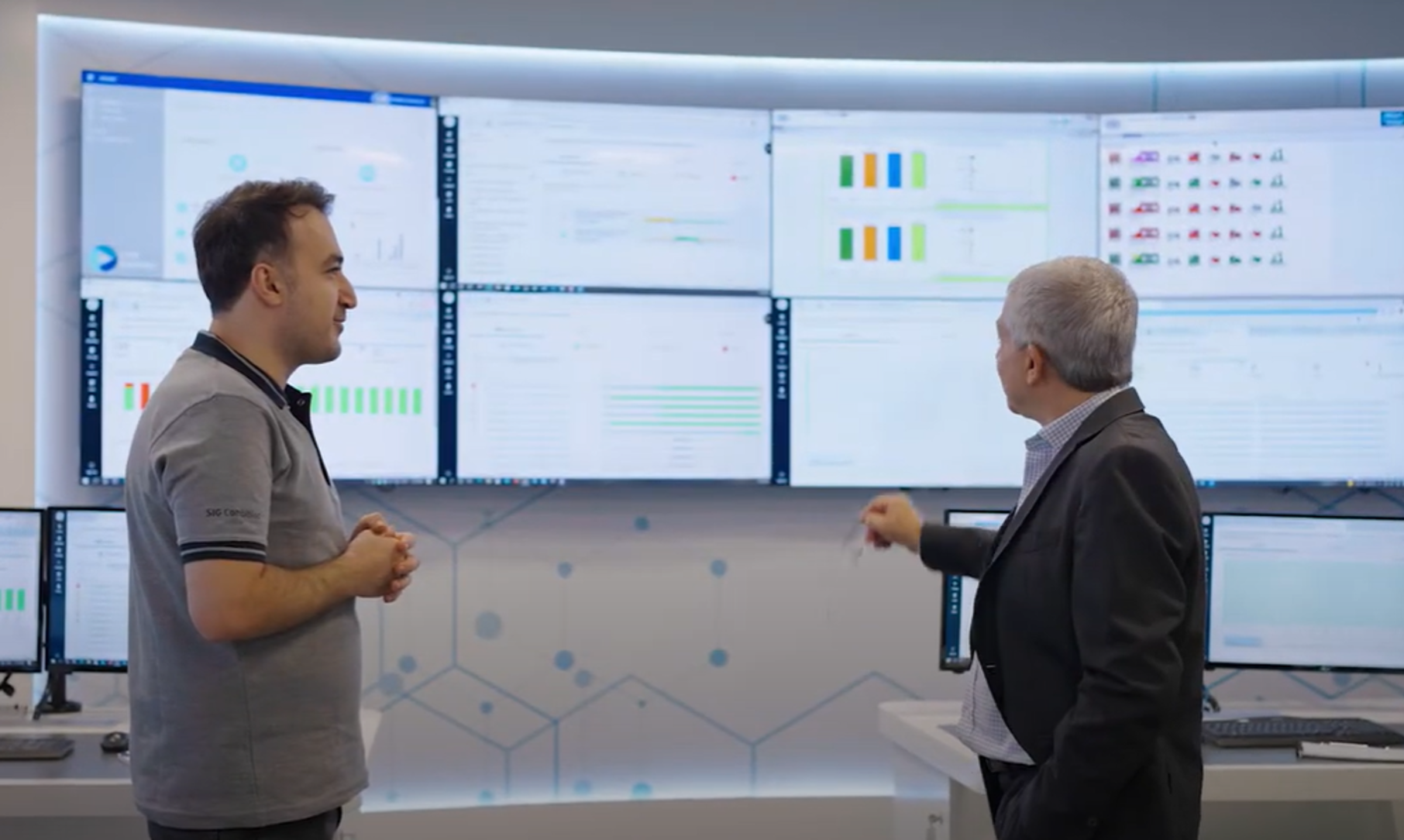

To make maintenance more proactive, we’re using digital tools to effectively monitor assets, avoid breakdowns, and improve operations.

Anticipate what your machinery needs

How does SIG Asset Health Monitoring work?

- Improve availability and avoid unplanned downtime: Our monitoring solution prevents unplanned downtimes by tracking vital parts of the filling line and proactively informing customers of performance.

- Expert-analyzed data: Senior SIG experts monitor filling lines at our Reliability Centers to prevent and anticipate downtimes before they occur and make predictive assessments about equipment performance.

- Steady improvements: Continuous monitoring and reports help consumers make improvements over time.

案例研究:Almarai

Almarai 是中东和非洲 (MEA) 最大的乳品制造和分销公司。Almarai 位于沙特阿拉伯,利用 SIG Asset Monitoring 来避免停机并优化生产:

"SIG 的智能工厂解决方案,包括 SIG Asset Monitoring,可对我们的各种灌装线参数进行必要的监控,并 提示任何异常情况。这种持续的反馈和纠正措施 使我们能够避免灌装线在运行过程中出现意外停机。"

Learn how SIG Asset Health Monitoring—along with all our Digital Solutions—can reduce downtimes and optimize availability.