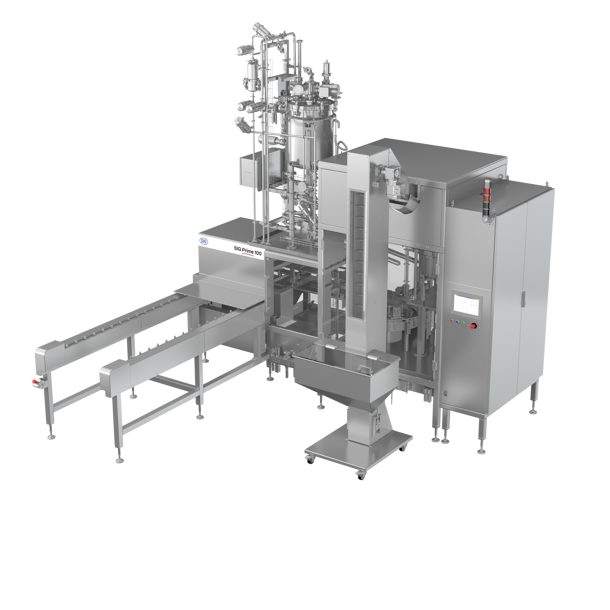

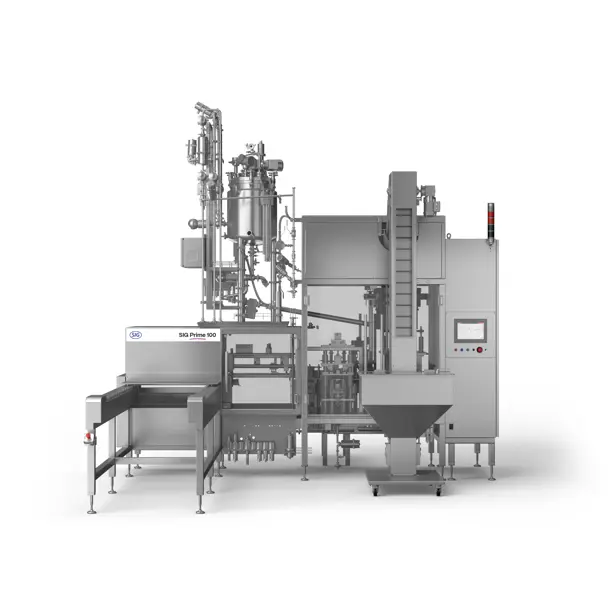

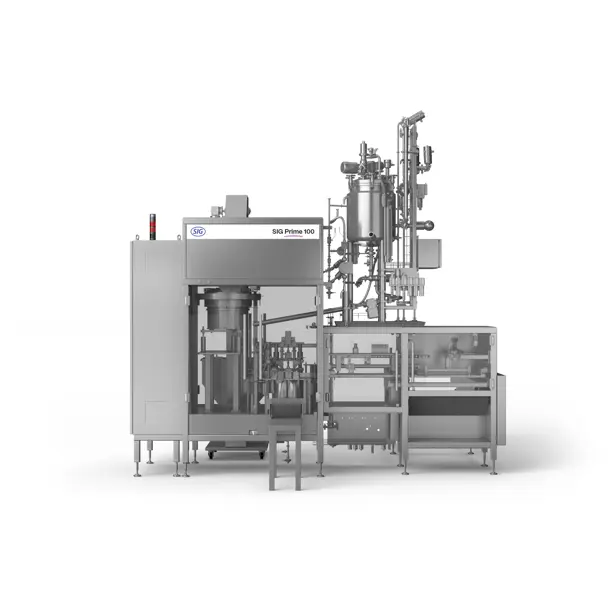

The standard in spouted pouch filling

Built to handle a range of filling requirements, the SIG Prime 100 ensures product safety, integrity, and shelf-life without compromise. Its precise temperature control and flexible filling technology make it ideal for baby and toddler food, fruit puree, and yogurt.

Key features

The Prime 100 offers high-speed filling and capping specifically for hot-fill applications while ensuring gentle product handling to maintain quality and taste. Its modular design allows for easy integration into existing production lines, supporting a broad range of container formats and sizes. Efficient energy and resource use helps reduce operating costs while maintaining production flexibility.

This system has visual warning indicators, a messaging system that displays fault condition(s) and, if necessary, stops the filling operation. In addition, if necessary, product may be automatically diverted away from the filler with messaging to upstream processing control. Clean-in-place (CIP) and sterilize-in-place (SIP) machine cycles are applicable.

Product benefits

Utilizes hot-fill packaging technology, ensuring an extended shelf life for your products and maintaining their freshness and quality.

Integrated aseptic zone ensures the spout and plug are kept sterile throughout the filling process.

The unique design options allow you to create a unique packaging solution that stands out on the shelf, enhancing brand recognition and differentiation.

How it works

Known process applications

Hot-fill

Fills heated, commercially-sterile product in non-sterile packaging. Can reduce product taste and texture.

Fresh

Occurs when a product is filled into a package with no additional sterilization treatment.

Package sizes

Don't see the size you need? Contact us for more information.

Filling speeds

| Package Size | Filling Speed* | |

|---|---|---|

| mL | Liters per minute | Pouches per minute |

| 118.0 | 227 | 100 |

| 177.0 | 227 | 75 |

| 237.0 | 227 | 69 |

* The output shown is based on water supplied at 240 liters per minute. Actual output from the filling equipment may vary depending on several factors, including – but not limited to – product viscosity, package size, fitment type, and product supply rate. The output provided is typical and intended for reference only; it does not constitute a specification. Customers are responsible for confirming performance through their own product testing.

Servicing your machine

We transform operations for better by providing superior system quality, performance, and value though industry-leading solutions. From preventative maintenance to asset monitoring and end-to-end traceability, we offer a variety of service options to keep your equipment up and running with the best possible OEE.

Related solutions