Гибкость во всём

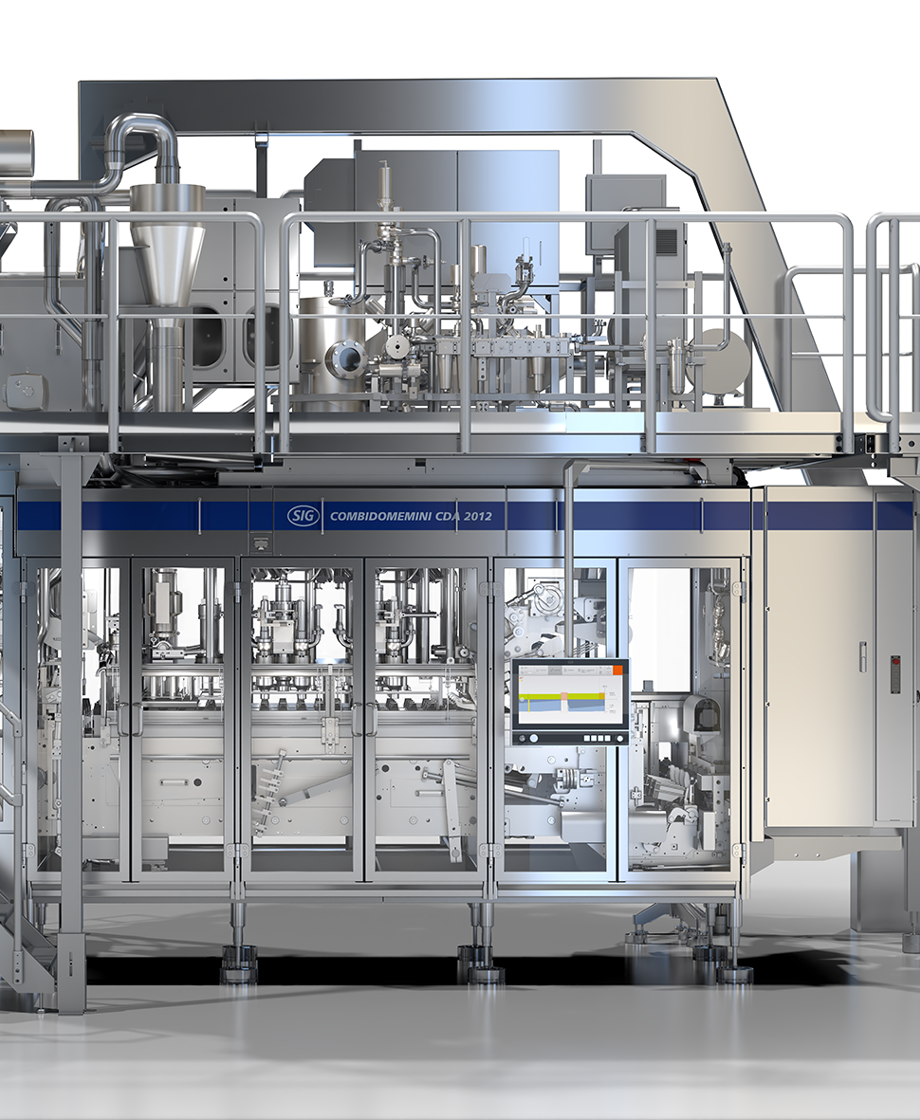

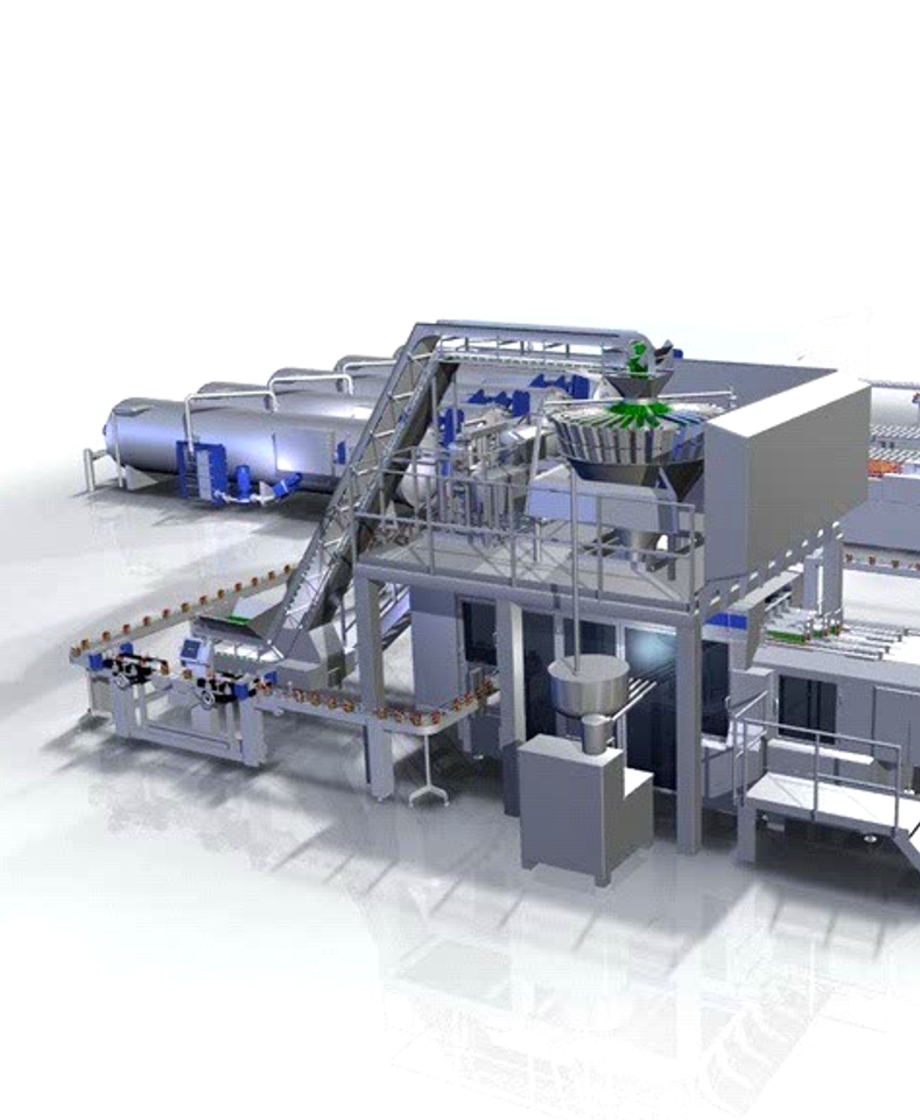

Технология розлива SIG отличается непревзойденной гибкостью. При одинаковых базовых параметрах мы предлагаем самое быстрое в отрасли время переналадки форматов, объёмов и дизайнов. В течение нескольких минут наши машины могут быть адаптированы для работы с девятью различными объёмами упаковок. Наше оборудование для розлива также совместимо с широким спектром другого оборудования сторонних производителей, что обеспечивает вам полную гибкость в выборе технологических партнеров.

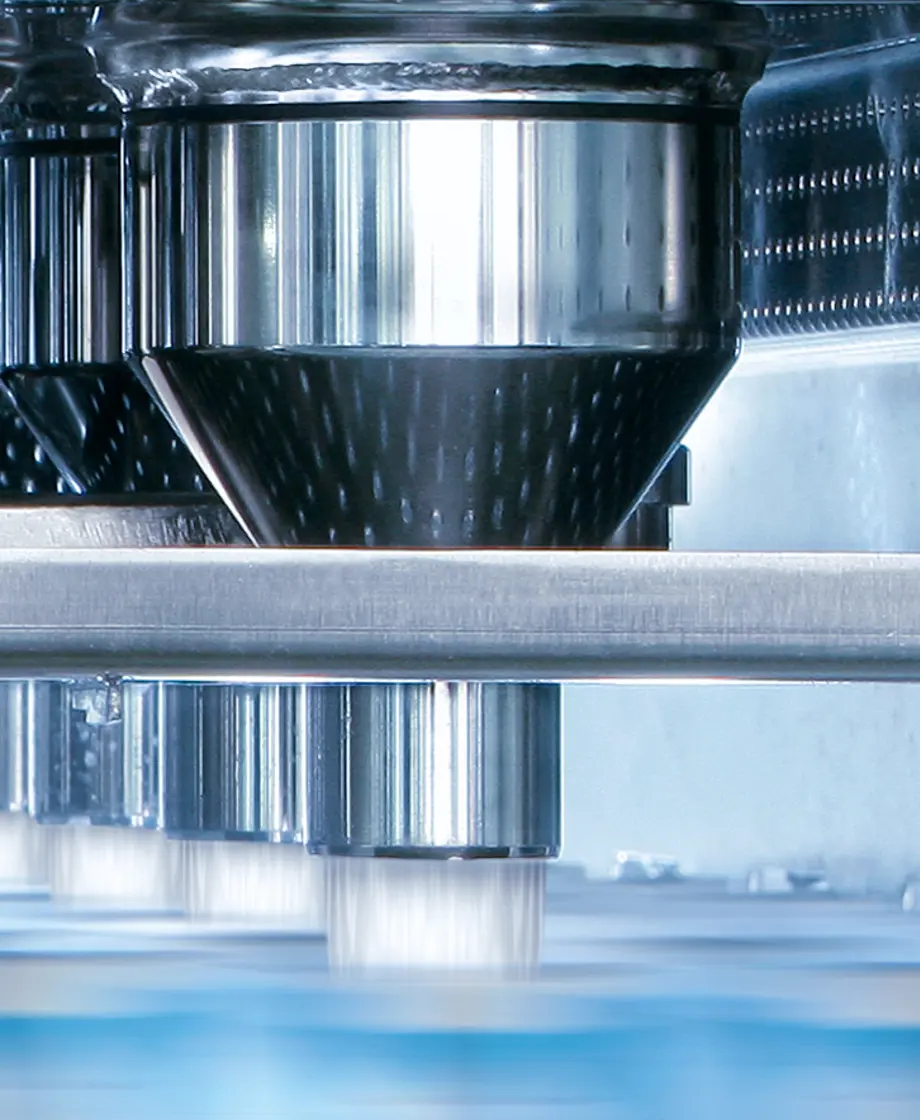

Преимущество асептической технологии розлива

Асептический розлив обеспечивает высочайшие стандарты безопасности и качества продуктов питания, а также помогает сохранить питательные вещества, аромат и цвет.

- Срок хранения до 12 месяцев без охлаждения и консервантов.

- Наш технологический процесс позволяет производить асептический розлив широкого спектра продуктов.

Высокая эффективность, низкий уровень отходов

Наши машины для розлива способны наполнять до 24000 упаковок в час и отвечают самым высоким критериям производительности для компаний, работающих в сфере продуктов питания и напитков. Такая скорость в сочетании с невероятно низким уровнем отходов и уникальной гибкостью обеспечивает высокую эффективность и низкие системные затраты.

А благодаря прочной, хорошо продуманной конструкции вы можете быть уверены, что машины будут надёжно работать в течение многих лет. С помощью наших стандартных машин для розлива возможно производить розлив в стандартную картонную упаковку три основных категории продукции: жидкие молочные и растительные напитки, негазированные безалкогольные напитки (NCSD) и жидкие пищевые продукты.

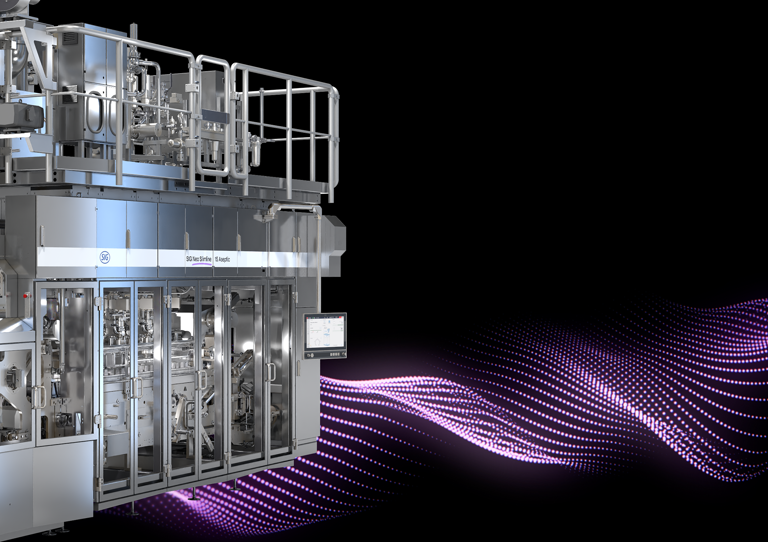

SIG Neo. The next big step in aseptic technology

SIG is expanding its SIG Neo filling machine portfolio launching another cutting-edge filling machine for multi-serve aseptic carton packs, capable of filling up to 15,000 SIG SlimlineBloc packs per hour – a 25% increase in output compared to SIG’s standard filling machines for family-sized formats.

Варианты розлива пищевых продуктов

Процесс розлива в готовую высечку обеспечивает широкий спектр возможностей для вашей продукции. С помощью наших стандартных машин можно производить розлив трёх категорий продуктов в стандартную картонную упаковку: жидкие молочные и растительные напитки, негазированные безалкогольные напитки (NCSD) и жидкие пищевые продукты. Чтобы добавить ценности вашему ассортименту, мы предлагаем дополнительные опции для расширения линейки продуктов, которые можно разливать на наших стандартных машинах: SIG Drinksplus для повышения ценности любого напитка и Food Options для расширения возможностей при работе с жидкими пищевыми продуктами.

Для пищевых продуктов с частицами размером до 25 мм мы используем специальные пищевые структуры и машины для розлива. Однако, мы не ограничиваемся этим и предлагаем ретортную систему для всех продуктов, которым не подходит асептическая технология.