Une solution de remplissage fiable

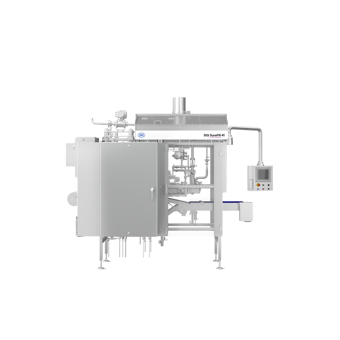

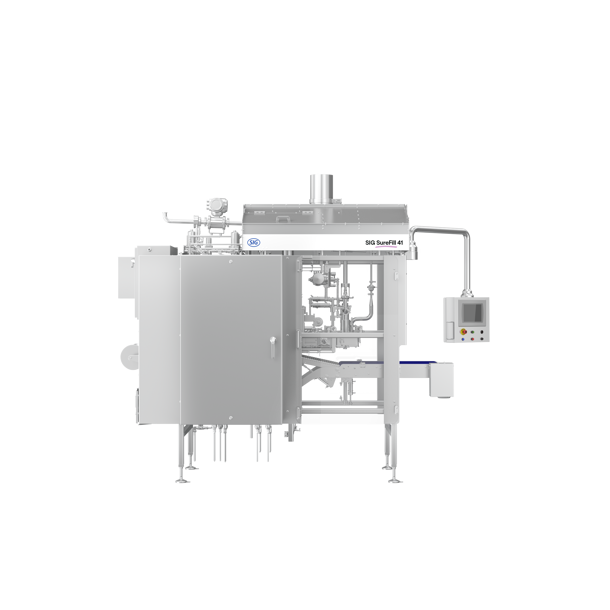

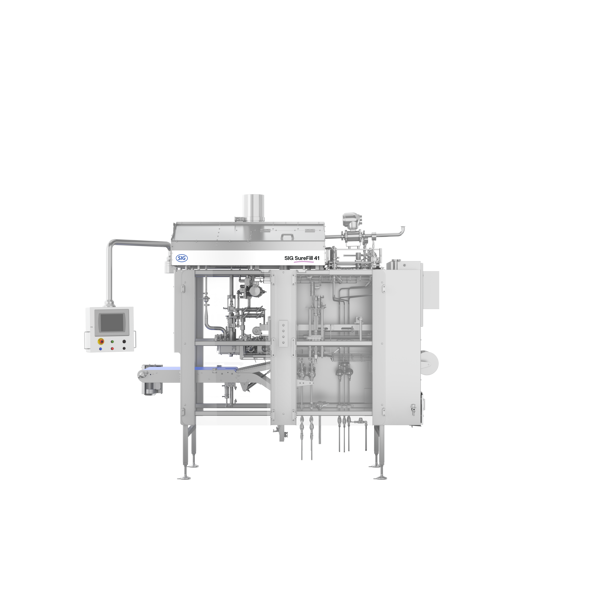

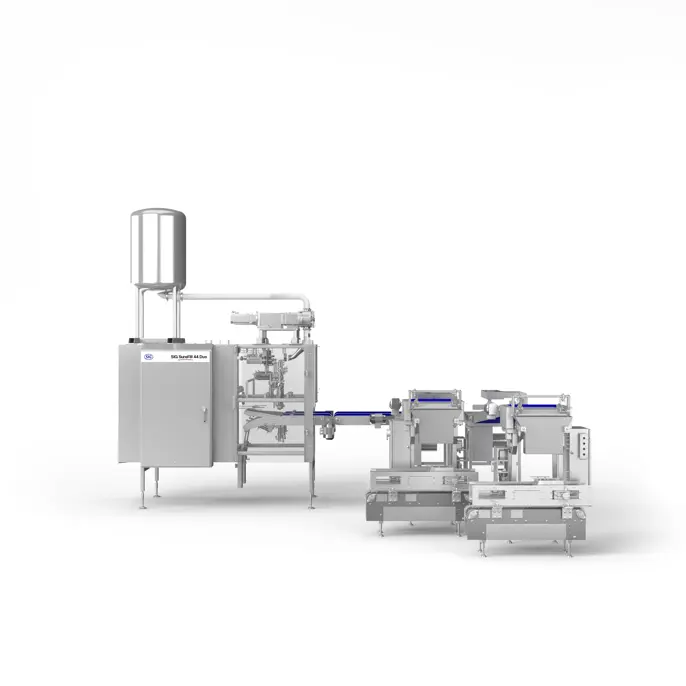

The SIG SureFill 41 is a state-of-the-art bag-in-box filling equipment that combines speed, accuracy, and reliability to meet the demands of your packaging operations. With its advanced technology and user-friendly interface, it enables efficient and precise filling of liquid products.

- Ensures optimal product quality and shelf life

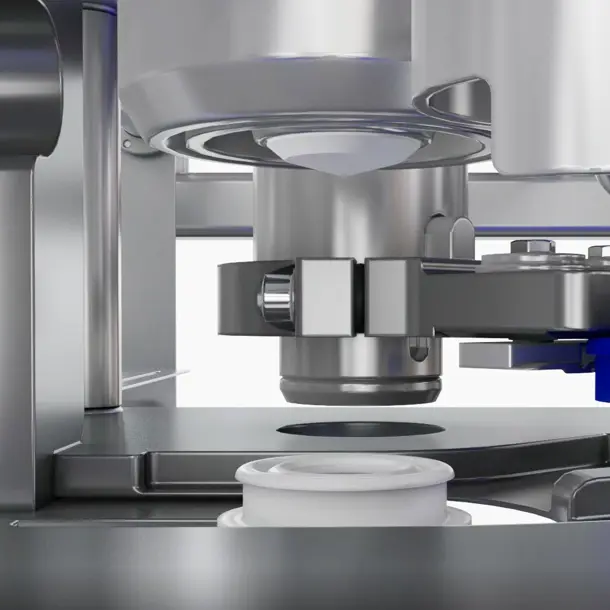

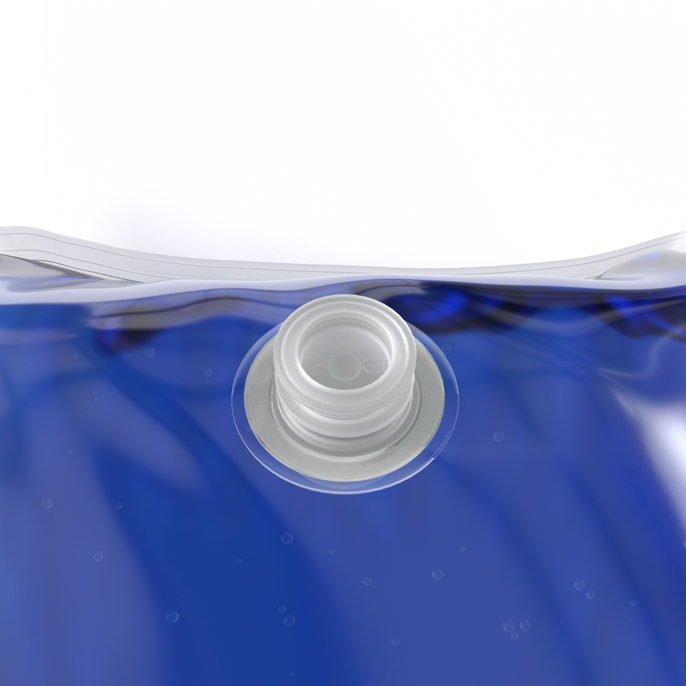

- Features patented sterilization technology

- Keeps your products safe and sterile throughout filling process

Caractéristiques principales

The SIG SureFill 41 is a single-lane, automatic web filling machine. The machine is capable of packaging extended shelf life (ESL), high-acid (HA), and low-acid (LA) products in 3- to 24-liter bag-in-box sizes. The filler is equipped with an Allen Bradley PLC interface utilizing panel view plus HMI. To ensure optimal process conditions, this interface system also includes optional visual warning indicators as well as a messaging system that displays fault condition(s) and can, if necessary, stop the filling operation and the state-of-the-art system allows product to be automatically diverted away from the filler with messaging to upstream processing control. All product contact surfaces are constructed out of 316L stainless steel.

This system also has optional visual warning indicators; a messaging system that displays fault condition(s) and, if necessary, stops the filling operation. In addition, if necessary, product may be automatically diverted away from the filler with messaging to upstream processing control.

This filler is of modular design and can be configured to address a variety of packaging and bag loading options: from flat drop to end loading configurations.

Also available with optional Speed-Up Kit that can increase throughput by up to 15%.

Avantages du produit

The SIG SureFill 41 maximizes production efficiency with its compact design and quick changeover capabilities.

With its precise filling (within .5 of a percent) the SIG SureFill 41 ensures accurate dosing and consistent product quality.

With an easy-to-use HMI, the SIG SureFill 41 keeps things simple and easy to operate with minimal training.

The integrated control system of the SIG SureFill 41 ensures reliable performance and consistent production output.

Comment ça marche

Applications de processus connues

Fresh

Occurs when a product is filled into a package with no additional sterilization treatment.

Ultra-clean (ESL)

Uses UV and/or hydrogen peroxide in combination with laminar flow to achieve high hygienic levels for short shelf-life products.

Aseptic

Fills commercially-sterilized products into pre-sterilized packaging. Products can be held unopened without refrigeration.

Tailles des emballages

Don't see the size you need? Contact us for more information.

Vitesses de remplissage

| Taille de l’emballage | Vitesse de remplissage* | |

|---|---|---|

| (L) | (Litres par minute) | (Bags par minute) |

| 3.0 | 227 | 13-15 |

| 4.0 | 227 | 12-14 |

| 5.0 | 227 | 11-13 |

| 10.0 | 227 | 9-10 |

| 20.0 | 227 | 6-7 |

* The output shown is based on water supplied at 240 liters per minute. Actual output from the filling equipment may vary depending on several factors, including – but not limited to – product viscosity, package size, fitment type, and product supply rate. The output provided is typical and intended for reference only; it does not constitute a specification. Customers are responsible for confirming performance through their own product testing.

Catégories de produits

- Aliments à tartiner et nappages

- Aliments pour bébés et jeunes enfants

- Boissons à base de jus

- Boissons alcoolisées

- Café et thé

- Concentrés de boissons

- Condiments

- Crème

- Crèmes glacées

- Eau

- Fluides automobiles

- Fruits et légumes

- Huile alimentaire

- Lait nature

- Peintures et revêtements

- Produits d’entretien

- Produits d’hygiène et de beauté

- Produits laitiers fonctionnels

- Sauces

- Smoothies

- Substituts de repas

- Végétarien

- Yaourt

- Yaourts à boire

Maintenance de votre machine

Nous transformons les opérations pour les rendre plus performantes en offrant une qualité, une performance et une valeur exceptionnelles grâce à des solutions de pointe. De la maintenance préventive à la surveillance des équipements, en passant par la traçabilité complète, nous proposons une gamme d’options de service pour garantir que vos équipements fonctionnent en continu avec un OEE optimal.

Solutions associées

À la recherche d’un co-packer ?

SIG peut vous aider !

* The output shown is based on water supplied at 240 liters per minute. Actual output from the filling equipment may vary depending on several factors, including – but not limited to – product viscosity, package size, fitment type, and product supply rate. The output provided is typical and intended for reference only; it does not constitute a specification. Customers are responsible for confirming performance through their own product testing.